-

स्टीवनसीएचएन-टॉप बहुत अच्छी सेवा प्रदान करता है और उत्पाद हमारी बहुत मदद करते हैं

स्टीवनसीएचएन-टॉप बहुत अच्छी सेवा प्रदान करता है और उत्पाद हमारी बहुत मदद करते हैं -

एस.एन. शर्मासीएचएन-टॉप मशीन मुझे चीनी मशीनों के लिए अपने इम्प्रेशन को बेहतर बनाने में मदद करती है

एस.एन. शर्मासीएचएन-टॉप मशीन मुझे चीनी मशीनों के लिए अपने इम्प्रेशन को बेहतर बनाने में मदद करती है -

माइकसर्वोत्तम मूल्य के साथ सर्वोत्तम उत्पाद, सीएचएन-टॉप अच्छी तरह से किया!

माइकसर्वोत्तम मूल्य के साथ सर्वोत्तम उत्पाद, सीएचएन-टॉप अच्छी तरह से किया!

तापमान सीमा 600 800°C वैक्यूम ब्रेज़िंग पेस्ट पीसीडी पीसीबीएन कार्बाइड टूल्स के साथ संगत ब्रेज़िंग ब्रेज़िंग प्रक्रिया सुनिश्चित करना

नि: शुल्क नमूने और कूपन के लिए मुझसे संपर्क करें।

Whatsapp:0086 18588475571

WeChat: 0086 18588475571

स्काइप: sales10@aixton.com

यदि आपको कोई चिंता है, तो हम 24 घंटे ऑनलाइन सहायता प्रदान करते हैं।

x| Specific Gravity | 8.8 G/cm3 | Brazing Material | PCD PCBN Carbide Tools Brazing |

|---|---|---|---|

| Meltingpoint | 850-1100°C | Model No | 800-41/720-41/850-41 |

| Viscosity | Adjustable Depending On Formulation | Melting Point | 600-800°C |

| Model | Sil-Fos 5 | Appearance | Grey Paste |

| प्रमुखता देना | उच्च तापमान वैक्यूम ब्रेज़िंग पेस्ट,पीसीडी पीसीबीएन कार्बाइड ब्रेज़िंग पेस्ट,600-800 डिग्री सेल्सियस पर ब्राज़िंग पेस्ट |

||

उत्पाद का वर्णन:

वैक्यूम ब्रेज़िंग पेस्ट एक उच्च गुणवत्ता वाला प्रवाह है जिसे विशेष रूप से वैक्यूम ब्रेज़िंग अनुप्रयोगों में उपयोग के लिए डिज़ाइन किया गया है, विशेष रूप से कार्बाइड सामग्री को जोड़ने के लिए उपयुक्त है। यह ब्रेज़िंग पेस्ट,अक्सर कार्बाइड के लिए ब्रेज़िंग पेस्ट के रूप में जाना जाता है, मजबूत, टिकाऊ जोड़ों को बनाने में उत्कृष्ट प्रदर्शन प्रदान करता है जबकि संयुक्त सामग्रियों की अखंडता को बनाए रखता है।इसकी अनूठी संरचना अनुकूलित गीलापन और प्रवाह विशेषताओं को सुनिश्चित करती है, जिससे यह सटीक लेजिंग कार्यों के लिए एक आवश्यक यौगिक बन जाता है।

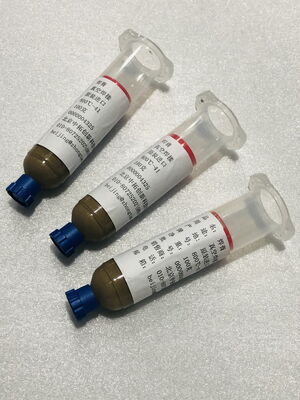

100 ग्राम के कंटेनर में आसानी से पैक किया गया, यह वैक्यूम ब्रेज़िंग पेस्ट कंपाउंड संभालना और लागू करना आसान है, जिससे उपयोगकर्ताओं को उनकी ब्रेज़िंग आवश्यकताओं के लिए एक लागत प्रभावी और कुशल समाधान प्रदान होता है।पेस्ट की स्थिरता ऐसे सतहों पर आसानी से लागू करने की अनुमति देती है जिन्हें जोड़ने की आवश्यकता होती हैचाहे औद्योगिक निर्माण या विशेष मरम्मत कार्य में उपयोग किया जाए, यह फ्लक्स पेस्ट विश्वसनीय और प्रभावी साबित होता है।

इस वैक्यूम ब्रेज़िंग पेस्ट का पिघलने का बिंदु 850°C से 1100°C के बीच सावधानीपूर्वक नियंत्रित किया जाता है, जिससे यह विभिन्न प्रकार के ब्रेज़िंग तापमान आवश्यकताओं के लिए उपयुक्त हो जाता है।यह रेंज संवेदनशील कार्बाइड सब्सट्रेट को नुकसान पहुंचाए बिना मजबूत धातु विज्ञान बंधन प्राप्त करने के लिए आदर्श हैइसके अतिरिक्त, प्रवाह सामग्री का मूल पिघलने का बिंदु 600°C से 800°C के बीच होता है, जो ब्राज़िंग प्रक्रिया के दौरान धातु की सतहों को सक्रिय करने और साफ करने में सुविधा प्रदान करता है।यह दोहरी पिघलने बिंदु विशेषता यह सुनिश्चित करती है कि पेस्ट वैक्यूम स्थितियों में कुशलता से प्रदर्शन करता है, उत्कृष्ट केशिका क्रिया को बढ़ावा देता है और ऑक्सीकरण को कम करता है।

इस वैक्यूम ब्रेज़िंग पेस्ट की एक खास विशेषता यह है कि यह वैक्यूम वातावरण में प्रभावी ढंग से कार्य करने में सक्षम है।वैक्यूम ब्रेज़िंग कार्बाइड जैसी उच्च प्रदर्शन वाली सामग्रियों को जोड़ने के लिए एक पसंदीदा विधि है क्योंकि यह संदूषण और ऑक्सीकरण को कम करती हैवैक्यूम ब्रेज़िंग पेस्ट कंपाउंड इस प्रक्रिया का पूरक है, जो धातु की सतहों से ऑक्साइड और अशुद्धियों को हटाने के लिए आवश्यक प्रवाह गतिविधि प्रदान करता है,इस प्रकार भराव धातु की गीलापन और प्रवाह को बढ़ाना.

संरचना के संदर्भ में, वैक्यूम ब्रेज़िंग पेस्ट एक प्रवाह सामग्री पर आधारित है जिसे सख्त गुणवत्ता मानकों को पूरा करने के लिए इंजीनियर किया गया है। इसकी फॉर्मूलेशन, जिसे इसके मूल पदनाम 800-41 द्वारा जाना जाता है,यह सुनिश्चित करता है कि यह न्यूनतम अवशेषों के साथ लगातार प्रदर्शन प्रदान करता है. ब्राजिंग के बाद, अवशेषों को आसानी से साफ किया जा सकता है, जो साफ और पेशेवर गुणवत्ता वाले जोड़ों को पीछे छोड़ देता है।यह पेस्ट विशेष रूप से उन उद्योगों में पसंद किया जाता है जहां सटीकता और स्वच्छता सर्वोपरि है, जैसे एयरोस्पेस, ऑटोमोबाइल और टूलींग सेक्टर।

कार्बाइड के लिए इस ब्राज़िंग पेस्ट का आवेदन सीधा और उपयोगकर्ता के अनुकूल है। यह मैन्युअल रूप से या स्वचालित वितरण प्रणालियों का उपयोग करके लागू किया जा सकता है,उत्पादन या मरम्मत के पैमाने के आधार पर लचीलापन की अनुमतिपेस्ट की स्थिरता और शेल्फ जीवन भी इसकी व्यावहारिकता में योगदान देता है, क्योंकि यह उचित रूप से संग्रहीत होने पर समय के साथ प्रभावी रहता है।यह विश्वसनीयता इसे उन पेशेवरों के बीच पसंदीदा विकल्प बनाती है जिन्हें विश्वसनीय प्रवाह सामग्री की आवश्यकता होती है जो कठिन परिस्थितियों में लगातार प्रदर्शन करती है.

कुल मिलाकर, वैक्यूम ब्रेज़िंग पेस्ट कार्बाइड और अन्य कठोर धातुओं के ब्रेज़िंग में शामिल किसी भी व्यक्ति के लिए एक अपरिहार्य उत्पाद है।और वैक्यूम ब्रेज़िंग प्रक्रियाओं के साथ संगतता इसे मजबूत प्राप्त करने के लिए एक बेहतर विकल्प बनाते हैंचाहे आप काटने के औजारों, पहनने के प्रतिरोधी घटकों, या सटीक इकट्ठा पर काम कर रहे हैं, इस वैक्यूम ब्रेज़िंग पेस्ट यौगिक हर आवेदन के साथ इष्टतम परिणाम सुनिश्चित करता है।

संक्षेप में, यह वैक्यूम ब्रेज़िंग पेस्ट प्रदान करता हैः

- पैकेज का आकारः उपयोग और भंडारण में आसानी के लिए सुविधाजनक 100 ग्राम का कंटेनर।

- पिघलने का बिंदु सीमाः 850-1100°C, उच्च तापमान पट्टे के लिए उपयुक्त है।

- प्रभावी सक्रियण और सफाई के लिए मूल पिघलने बिंदु के साथ प्रवाह सामग्रीः 600-800°C.

- विशेष रूप से कार्बाइड के लिए ब्राज़िंग पेस्ट के रूप में डिज़ाइन किया गया, उत्कृष्ट संगतता और प्रदर्शन सुनिश्चित करता है।

- वैक्यूम ब्रेज़िंग प्रक्रियाओं के लिए अनुकूलित, ऑक्सीकरण और संदूषण को कम करना।

- मूल 800-41 के रूप में जाना जाता है, जो निरंतर गुणवत्ता और विश्वसनीय परिणामों की गारंटी देता है।

बेहतर बंधन शक्ति, स्वच्छ जोड़ों और बढ़ी हुई स्थायित्व का अनुभव करने के लिए अपनी अगली ब्रेज़िंग परियोजना के लिए इस वैक्यूम ब्रेज़िंग पेस्ट कंपाउंड का चयन करें।यह पेशेवरों के लिए आदर्श प्रवाह पेस्ट है जो अपने ब्रेज़िंग कार्यों में सटीकता और उत्कृष्टता की मांग करते हैं.

विशेषताएं:

- उत्पाद का नाम: वैक्यूम ब्रेज़िंग पेस्ट

- विशिष्ट गुरुत्वाकर्षणः 8.8 G/cm3

- मूल मॉडल: 800-41

- उपलब्ध मॉडल: 800-41 / 720-41 / 850-41

- रंगः भूरा

- पैकेज का आकारः 100 ग्राम

- उच्च गुणवत्ता वाले वैक्यूम ब्रेज़िंग पेस्ट यौगिक

- प्रभावी वैक्यूम ब्रेज़िंग समाधान विभिन्न धातु मिलान अनुप्रयोगों के लिए उपयुक्त

- विश्वसनीय वैक्यूम वेल्डिंग पेस्ट जो वैक्यूम वातावरण में मजबूत और स्वच्छ वेल्ड सुनिश्चित करता है

अनुप्रयोग:

CTSTC वैक्यूम ब्रेज़िंग पेस्ट, मॉडल संख्या 800-41, एक उच्च गुणवत्ता वाली फ्लक्स सामग्री है जिसे विशेष रूप से वैक्यूम ब्रेज़िंग अनुप्रयोगों के लिए तैयार किया गया है।उत्कृष्ट गीलापन और मजबूत जोड़ों के गठन के लिए डिज़ाइन किया गया, यह वैक्यूम ब्रेज़िंग पेस्ट सटीक और विश्वसनीय ब्रेज़िंग परिणामों की आवश्यकता वाले उद्योगों के लिए आदर्श है। इसके फॉर्मूलेशन के आधार पर समायोज्य चिपचिपाहट बहुमुखी उपयोग की अनुमति देती है,इसे विभिन्न ब्रेज़िंग तकनीकों और घटक ज्यामिति के लिए उपयुक्त बनाना.

सीटीएसटीसी वैक्यूम ब्रेज़िंग पेस्ट के लिए प्राथमिक अनुप्रयोग अवसरों में से एक हीट एक्सचेंजर के निर्माण में है, जहां मजबूत, लीक-प्रूफ जोड़ महत्वपूर्ण हैं।पेस्ट का भूरा रंग और सुसंगत संरचना निर्बाध परिस्थितियों में एक समान आवेदन और इष्टतम ब्रेज़िंग प्रदर्शन सुनिश्चित करती हैइसके अतिरिक्त, इसका उपयोग ऑटोमोटिव और एयरोस्पेस क्षेत्रों में जटिल धातु इकट्ठा करने के लिए किया जाता है जो उच्च शक्ति और संक्षारण प्रतिरोध की आवश्यकता होती है।

इलेक्ट्रॉनिक्स विनिर्माण में, वैक्यूम ब्रेज़िंग पेस्ट जटिल घटकों और हीट सिंक को जोड़ने में सुविधा प्रदान करता है, थर्मल चालकता और यांत्रिक स्थिरता को बढ़ाता है।उत्पाद की सुविधाजनक सिरिंजों में पैकेजिंग सटीक वितरण की अनुमति देती हैयह केवल 10 ग्राम की न्यूनतम ऑर्डर मात्रा के साथ छोटे पैमाने पर प्रोटोटाइप और बड़े उत्पादन रनों दोनों को पूरा करता है।

सीटीएसटीसी की प्रति दिन 1000 ग्राम की आपूर्ति क्षमता और 5-10 दिनों की डिलीवरी का समय इस वैक्यूम ब्रेज़िंग पेस्ट को समय पर परियोजना पूरा करने के लिए एक विश्वसनीय विकल्प बनाता है।विभिन्न बजट आवश्यकताओं को पूरा करना, जबकि भुगतान की शर्तों में टीटी, एलसी और वेस्टर्न यूनियन शामिल हैं, जो वैश्विक ग्राहकों को लचीलापन प्रदान करते हैं।विभिन्न ब्रेज़िंग आवश्यकताओं के अनुरूप विकल्प प्रदान करता है.

कुल मिलाकर, CTSTC वैक्यूम ब्रेज़िंग पेस्ट कई उद्योगों में उच्च परिशुद्धता, उच्च गुणवत्ता वाले ब्रेज़िंग परिदृश्यों के लिए पूरी तरह से उपयुक्त है। चाहे प्रोटोटाइपिंग या बड़े पैमाने पर उत्पादन के लिए,इसके उत्कृष्ट प्रदर्शन और अनुकूलन योग्य पैकेजिंग इसे उन्नत वैक्यूम ब्रेज़िंग प्रक्रियाओं के लिए एक अपरिहार्य सामग्री बनाते हैं.

सहायता एवं सेवाएं:

हमारे वैक्यूम ब्रेज़िंग पेस्ट को उच्च प्रदर्शन वाले ब्रेज़िंग अनुप्रयोगों के लिए बेहतर बंधन शक्ति और उत्कृष्ट थर्मल चालकता प्रदान करने के लिए डिज़ाइन किया गया है।हमारे विशेषज्ञों की टीम उत्पाद चयन में सहायता के लिए उपलब्ध है, अनुप्रयोग तकनीक, और इष्टतम परिणाम सुनिश्चित करने के लिए समस्या निवारण।

हम अनुकूलित सूत्र परामर्श, आवेदन प्रशिक्षण, और साइट पर तकनीकी सहायता सहित व्यापक सेवाएं प्रदान करते हैं ताकि आप अपनी ब्रेज़िंग प्रक्रियाओं की दक्षता और गुणवत्ता को अधिकतम करने में मदद कर सकें।सुरक्षित और प्रभावी उपयोग के लिए विस्तृत उत्पाद डेटाशीट और सुरक्षा जानकारी भी उपलब्ध है।.

सर्वोत्तम परिणामों के लिए, उत्पाद दिशानिर्देशों में उल्लिखित विशिष्ट तापमान प्रोफाइल और वैक्यूम स्थितियों का पालन करने की सिफारिश की जाती है।हमारी तकनीकी सहायता टीम आपके विशिष्ट आवेदन आवश्यकताओं के आधार पर अनुकूलित सिफारिशें प्रदान कर सकती है.

हम अपनी वैक्यूम ब्रेज़िंग पेस्ट के साथ विश्वसनीय और लगातार ब्रेज़िंग प्रदर्शन प्राप्त करने में आपकी सहायता करने के लिए असाधारण सेवा और समर्थन प्रदान करने के लिए प्रतिबद्ध हैं।